15.01.2025

H2 System Control

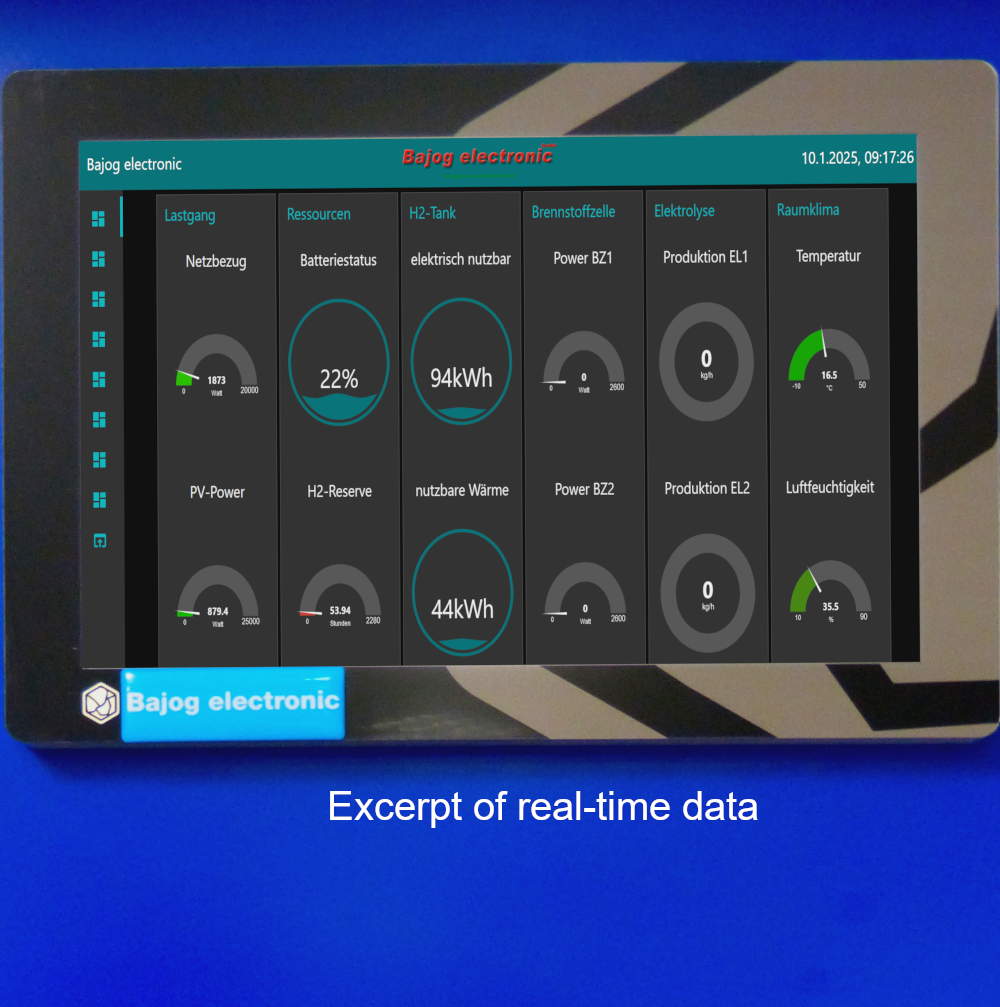

As with any complex system, a control and regulation unit must manage and monitor all processes. Bajog electronic has developed a control unit to securely and precisely manage all components of the Bajog energy storage system and to display all current operational states, including environmental parameters, online.

Safety Circuits:

The term „hydrogen“ is often associated by many people with explosions, bombs, and other dangers. In contrast, handling „gas“ is perceived as completely normal and everyday. However, it is often overlooked that an explosion with hydrogen is significantly harder to cause, and hydrogen in the atmosphere, unlike gas, does not pose a danger.

Of course, safety criteria and precautions must also be considered when dealing with hydrogen, just as with all energy carriers. These are all recorded, evaluated, controlled, visually displayed, and monitored with limit values in our safety concept.

Our safety circuits monitor:

- room air

- temperature

- humidity

- If even the smallest amounts of hydrogen are detected by the sensors, an online notification will be sent to all connected PCs, iPhones, iPads, or relevant monitors.

- If a defined limit is reached, the system will automatically deactivate.

- An alarm with a light signal will be activated, and the system operator will be notified via email. The same applies in the case of excessively high or low temperature and humidity values.

- In the case of a malfunction that is not safety-critical, the operation of the functional components will continue, and the operator will only be notified via email. This ensures high system reliability.

- The limit values we set are in the per-mille range.

System Control:

Our software and control unit manage and regulate all components of the H2 system (such as the fuel cell, electrolyzer, inverter, and H2 compressor).

The energy system itself is always adaptable and expandable. The individual components of the system are installed in one or more 19-inch enclosures, depending on the size of the system. The arrangement is highly customizable and can be configured to meet a variety of customer needs.

A control unit, for example, can be used for 2 fuel cells (each 2.5 kW) and 2 electrolyzers (each 2.4 kW). Additionally, the performance data from the PV inverters, charge controllers, and energy storage units are collected and evaluated by the control system to ensure the efficient operation of the entire system.

Even existing components can be integrated into our energy system under certain conditions.

The requirements for this integration are listed below.

- Energy Storage: The energy storage must be based on a 48-volt system.

- A suitable interface must be available to us.

- Inverters and Charge Controllers: The devices must be off-grid capable, meaning they must be able to provide emergency power in the event of a power failure.

- If you have a compressed air compressor with a power rating of at least 5.5 kW and a tank volume of at least 90 liters, we can use it for the H2 compressor’s operational air supply (if provided).

Since our guiding principle is always to pursue sustainability and cost-effectiveness, other existing components can also be integrated after discussion and thorough evaluation.